|

SHENZHEN HESHENGLONG PLASTIC PRODUCT CO., LTD.

|

Gold Index: 26184

You are here: home > ps blister for red wine > Flocking package tray for XO wine plastic flocking packing tray for Grape wine

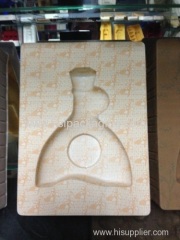

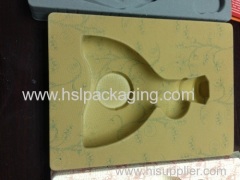

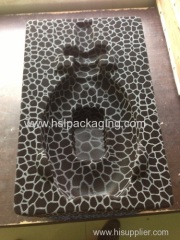

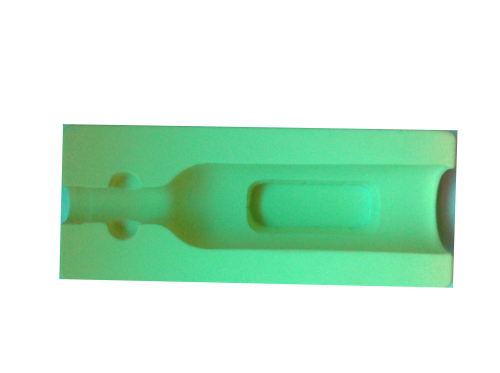

Flocking package tray for XO wine plastic flocking packing tray for Grape wine

| Price: | 0.2~0.7 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

HSL-HJ-24

Production Capacity:

20000 pcs/ month

Delivery Date:

7-10days after confirmation

suitable and rigid:

Good sealing property

PS,PVC with flocking:

High quality and favorable ...

Means of Transport:

Ocean,Land,Air

Packing:

carton box

Brand Name:

buyer's logo

Light and convenient to transport:

Transparent or nontranspare...

Specifications1.Flocking PS Clamshell,Blister Tray,Clamshell Blister

2.material :PS

3.High quality with the reasonable price

Plastic Flocking tray,Plastic Flocked packaging tray,PS Flocking packaging case, Plastic Packaging Tray, Plastic Tray, Blister tray is a kind of special material, it feels soft. Usually we stick a layer of flocking to a rigid plastic board, then it becomes a flocking tray.

Features:

1.Flocking is attractive, could be used to promote the grade of the product rank

2. Flocking packaging are widely used in many aspects, such as jewelry box, cosmetic packaging box, wine box, glasses box ,high -quality hardware and so on.

3. Any size and color are available according to your choice;

4. We run flexibly----OEM,Design and customize available;

5. Please contact us for more information.

Packaging Flocking Wine Tray

1.Blister tray material can be PPVC,PET,PP,PS, Flocking PS etc..

2.We can custom made as per your requirements.

3.Our packaging products are widely use for packing food, computer accessories, toys, stationery, mobile accessories, cosmetic parts and so on.

4.Customer's designs or samples are always warmly welcomed.

5.Offer ODM and OEM service.

Our advantage:

1. Advanced production equipment and fine workmanship of the employees.

2. Color, size. Material, thickness can according to customer request customized.

3. Fast response of competitive price, high quality, short time delivery, good service.

4. Certification: ISO9001: 2000 certification, Sedex certification.

5. Our packaging material are suitable for packing different products in different markets.

1. Advanced production equipment and fine workmanship of the employees.

2. Color, size. Material, thickness can according to customer request customized.

3. Fast response of competitive price, high quality, short time delivery, good service.

4. Certification: ISO9001: 2000 certification, Sedex certification.

5. Our packaging material are suitable for packing different products in different markets.

6. We have a R&D team here for you to innovate new design.

7.We have been in this business line for more than 13 years, products export worldwide.

8.We offer product packaging design free of charge for our clients.

We can produce the products according to your samples or design, the material can be PVC, PET, PP, PS, Flocking PS etc..

Our ability including tooling making, vacuum forming , extrusion, thermoforming, injection. All in one place insure our most competitive price and guarantee quality!Welcome to your inquiry !

We can produce the products according to your samples or design, the material can be PVC, PET, PP, PS, Flocking PS etc..

Our ability including tooling making, vacuum forming , extrusion, thermoforming, injection. All in one place insure our most competitive price and guarantee quality!Welcome to your inquiry !

Welcome to your inquiry!

| Type | Characteristics |

| Plaster Mold | Easy to reform and re-modification, Low Quality, for product development, tooling lead time 2 days |

| Copper Mold | High Transparence, Flow Mark relatively higher, Life Cycle-100,000 forming sheet, Tooling lead time 5-7days |

| Epoxy Mold | Shrinkage, High Transparence, Less Flow Mark, Life cycle-50,000 forming sheet, tooling lead time 7-10 days |

| Aluminum Mold | The Highest Transparence, Longest life cycle, Flow Mark relatively higher, tooling lead time 7-10 days |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

SHENZHEN HESHENGLONG PLASTIC PRODUCT CO., LTD. [China (Mainland)]

Business Type:Manufacturer

City: Shenzhen

Province/State: Guangdong

Country/Region: China (Mainland)

You May Like:

Product (324)

- PS tray for electricty (1)

- plastic packackage for pot (1)

- PP roll material (1)

- plastic product for tea box (17)

- ABS roll material (2)

- PS Leather look material (5)

- ps blister print series (16)

- ps blister tray for white wine (8)

- blister print and flock sheet series (5)

- ps sheet series (11)

- ps blister for red wine (189)

- ps blister for cosmetic (60)

- Others (8)