|

SHENZHEN HESHENGLONG PLASTIC PRODUCT CO., LTD.

|

Gold Index: 26184

You are here: home > ps blister for red wine > various material for plastic blister wine box

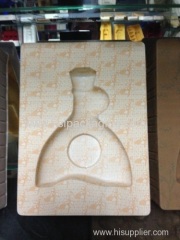

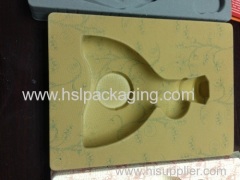

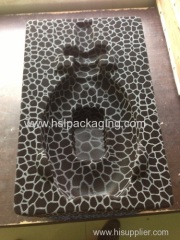

various material for plastic blister wine box

| Payment Terms: | T/T,L/C |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

HSL-BJ-02

Production Capacity:

50000PCS/ DAY

Delivery Date:

7-15 days after confirmatio...

square shape:

0.24mm - 1.2mm

Type:

Tray

Process Type:

Blister

Thickness:

2-8mm

Means of Transport:

Ocean,Land,Air

Packing:

CARTON

ps package:

Blister product

good looking:

good flocking on quality

Material:

Plastic

Custom Order:

Accept

plastic blister packing for wine

1.Material: PS ,PET ,PVC etc

2.Chinese Styles

3.To protect the product

4.OEM and new design accept

1.Professional design team design the most appropriate packaging as customer requirement.

2.silk-screen printing, offset printing, foil stamping, embossment effects for boxes are available.

3.We can provide the service of OEM.

4.With advanced equipment production exquisite products, ensure to provide you with top quality products

B.About the technology:

A.About the products:

1.Name: flocking blister and paper box for wine packing

2.Size:customized

3.Material:PVC,PET ,PS is available

4.Usage:packing for electronic ,hardware ,food,toy and so on

B.About the technology:

1.Blister cover:First vacuum thermoforming and then punching,a very easy process

2.Cramp-folding:cramp folding the blister and then pack into cartons

3.Cardboard:We also could supply the cardboard with good price

C.About all the material types we use:

1.PVC:a.Advantages:the cheapest and very commen material.Very easy to be sealed by heat sealing machine and high frequency.

b.Disadvantage:not environmental and nonflammable.Once flambe,it will produce chloration,what will do bad to the environment.

2.PS:a.Advantage:very easy to be vacuum thermoformed and it is environmental material.Always molded into trays,including flocky trays.Widely used in electron,medical,food,cosmetic,hardware and so on.

b.Disadvantage:relatively speaking,it is a bit fragile and easy to be torn off.

3.PP:a.Advantage:high melting point and can be microwaveable.Widely used in food packaging.

b.Disadvantage:shrink material,not easy to be vacuum thermoformed;has not passed the Halogen Free test but it is food grade material.

4.PET:PET has two types,one is APET,the other is PETG.Both have high transparency and are environmental material.APET could not be sealed by our machine but PETG can.PETG is the only one which has passed the Halogen Free test.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Blister Box

Plastic Blister

Blister Plastic

Plastic Material

Blister Light Box

Blister Folding Box

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

SHENZHEN HESHENGLONG PLASTIC PRODUCT CO., LTD. [China (Mainland)]

Business Type:Manufacturer

City: Shenzhen

Province/State: Guangdong

Country/Region: China (Mainland)

You May Like:

Product (324)

- PS tray for electricty (1)

- plastic packackage for pot (1)

- PP roll material (1)

- plastic product for tea box (17)

- ABS roll material (2)

- PS Leather look material (5)

- ps blister print series (16)

- ps blister tray for white wine (8)

- blister print and flock sheet series (5)

- ps sheet series (11)

- ps blister for red wine (189)

- ps blister for cosmetic (60)

- Others (8)